Electronics manufacturing

Green Manufacturing

Our highly qualified team of professionals, our modern manufacturing plant equipped with latest-generation machinery and our powerful computer system guarantee compliance with the strictest quality and traceability standards. Our production system is fully flexible to serve our customers' specific needs, encompassing automotive and industrial sector.

To ensure maximum reliability, all of our electronic equipment is inspected for correct operation.

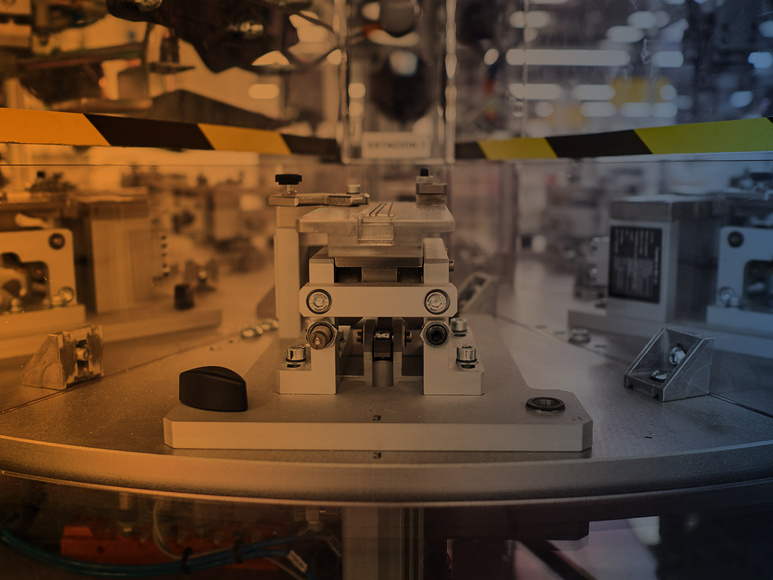

Electronic circuit assembly

Assembly of SMD and through-hole components

Three complete SMD assembly lines, with an insertion capacity in excess of 120,000 components/hour.

Screen prints, with a positioning repeatability of 3 sigma: +/- 0.005 mm, with high-resolution 2D vision camera.

Pick & place machines with capability for assembling all types of packaging: QFPs, QFNs, BGAs, uBGAs, LGAs, CSPs, POPs (Package on Package); fine-pitch components with pitch less than 0.5 mm; uBGA with a pitch less than 0.4 mm and a ball diameter less than 0.1 mm; and components with a broad range of sizes, from 01.005 to 45 x 100 mm.

7-zone reflow ovens, with controlled temperature profiles complying with the IPC standard, JEDEC J-STD-020.

AOI inspection, checking position, presence/absence, polarity, solder quality and values as appropriate.

Through-hole (THT) component assembly

Our Royonic machines, used for THT or conventional component insertion, enable us to assemble all types of special items and cables.

Soldering

Lead-free tin wave soldering (RoHS). Selective soldering.

Tropicalisation

We have automatic lines for applying silicones, polyurethanes and varnishes for circuit tropicalisation.

Automatic 5-axis machine with automatic nozzle change.

Overinjection with hot melt.

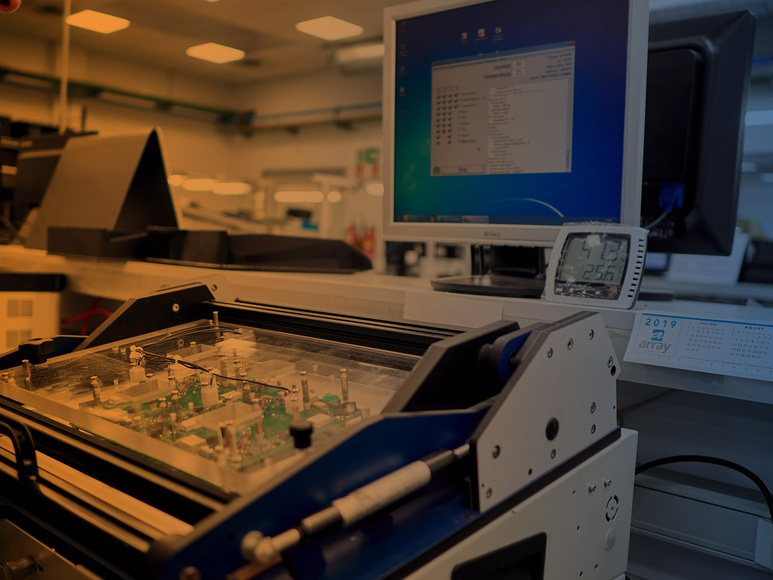

Verification

We are committed to assuring the highest quality. This means that all the electronic circuits and products manufactured by Elausa are functionally checked before delivery.

The scope of this functional check process is defined and agreed beforehand with the customer. The checkers and testing tools can be manufactured at Elausa or supplied by the customer, as agreed.

Finished product

Assembly of finished equipment and subassemblies.